RollerBall® Technical Details

Learn what makes RollerBall® sorters unique.

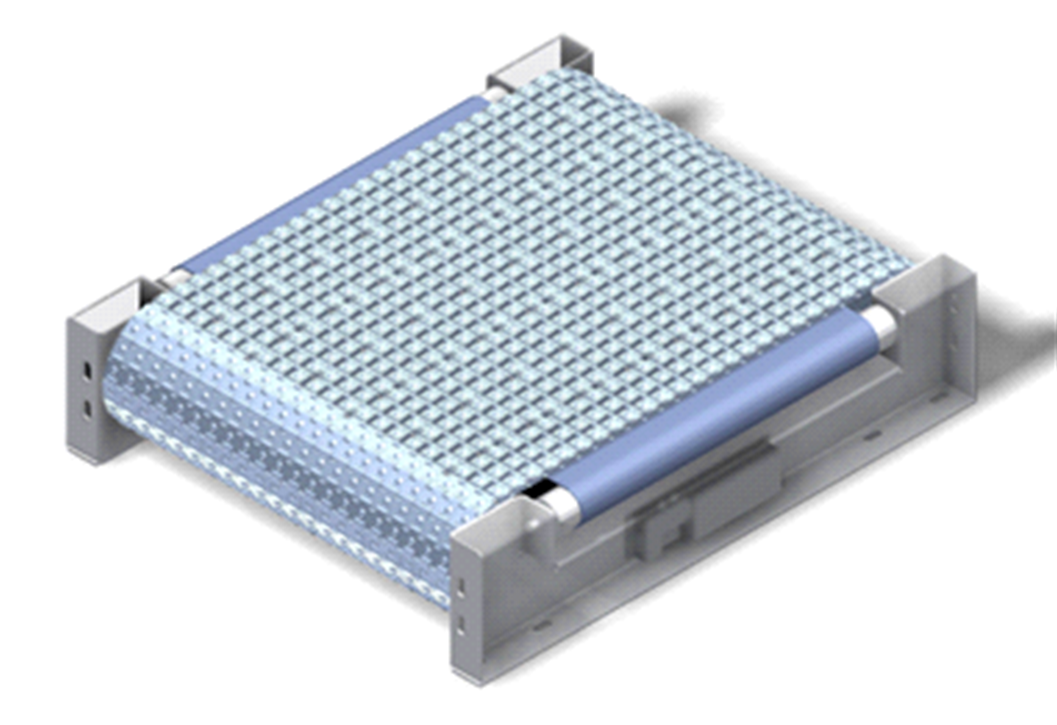

Roller Top Belt

Central to the ATR RollerBall® sorter design is the use of the System PlastTM 2253 RT Roller Top Belt of Regal Beloit. This plastic belting incorporates omnidirectional plastic balls captured in the belting surface at 1 inch centers.

The belt is an assembly of modular links incorporating the plastic balls. These interlocking links are joined together with plastic rods. The belting is available in nearly any width (in 3 inch increments) or length to suit application requirements.

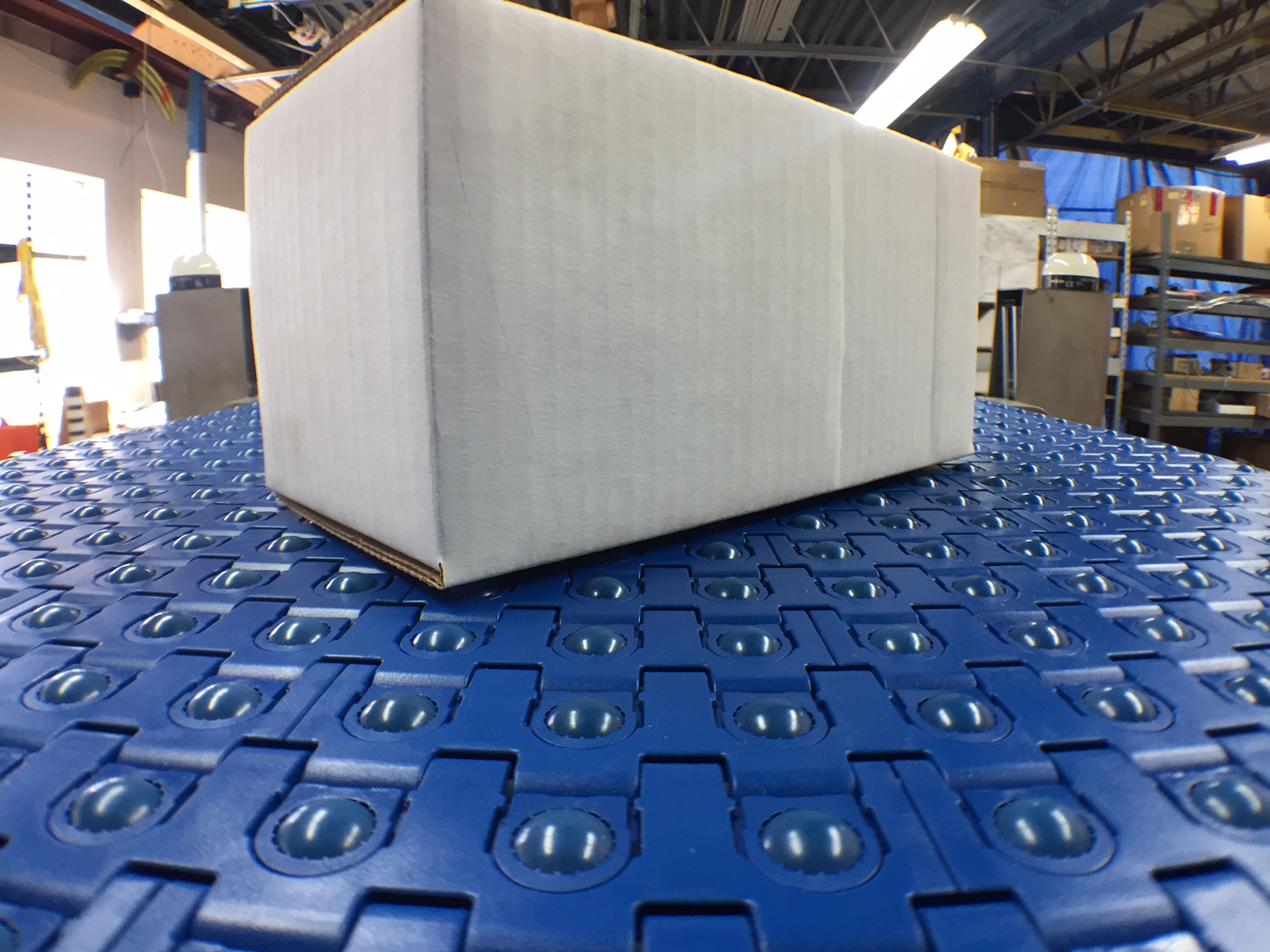

It is very effective for transporting light or heavy packages, including irregular packages such as floppies and pillow packs. The multiple contact points of the belting reliably transport such packages.

Envelopes

Anything from business card size through large mailing envelopes.

Magazines and Catalogs

The full variety of flats mail, including bundles.

Bags and Pillow Packs

Plastic, Tyvek®, and bubble wrap are easily transported.

Sort Module

This innovative patented technology is the heart of the RollerBall® sorter. Motorized drive rollers (MDR) power the belt to convey the product. The freely rotating spheres touch the surface underneath the belt causing them to rotate and move the product on their top surface. A second transverse-mounted fabric belt mounted underneath, also driven by MDR, moves the product to the right or left and off the main direction of flow.

Sensors between each section are used to track the product as it moves along the sorter. These array sensors detect even the smallest packages, providing reliable tracking of even the smallest and flattest packages, such as an CD case, or even a single post card!

Sort Section

- Pre-wired sections

- Easily moved by hand

- String together as many as you need

- Easily add or remove sections later

- Options include right-angle transfer

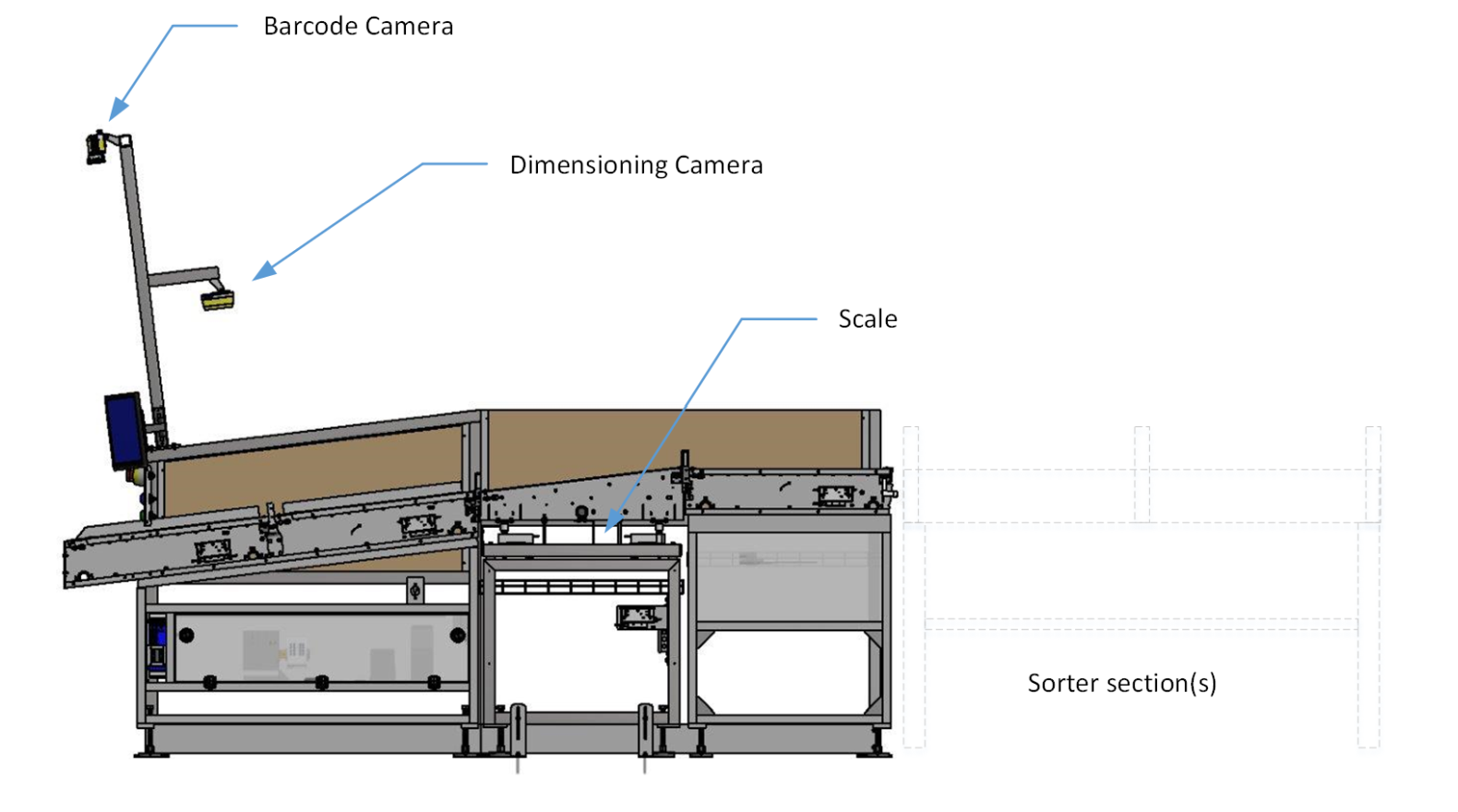

Induct Options

The induct system can be customized to meet your needs. Options include:

- Scanning

- Weighing

- Dimensioning

Additional options include printing and application of shipping labels for automated dispatch.

Scanning

Processing begins by “facing and placing” the package at the induct. An illuminated target region shows where to place the package, and an overhead scanner reads the package barcode(s).

As soon as a sortable barcode is detected, the package is automatically inducted. This intuitive face-and-place operation prevents no-read situations and minimizes rejects.

We currently support scanners from:

- Cognex

- Keyence

- Vitronic

Weighing

A high speed scale module is an option when package weight is needed. The scale module is physically isolated from the sorter to provide highest accuracy. The belt-driven conveyor section is supported with load cells that determine product weight through a summing box.

Dimensioning

Dimensioning is available for cuboidal packages. Package dimensions can be used to cull out oversized or undersized items, and to route based on size ranges. In addition, the control computer can track the total volume sorted to each bin, and flag when a bin is full or close to full. Standard and high-accuracy dimensioner options are available.

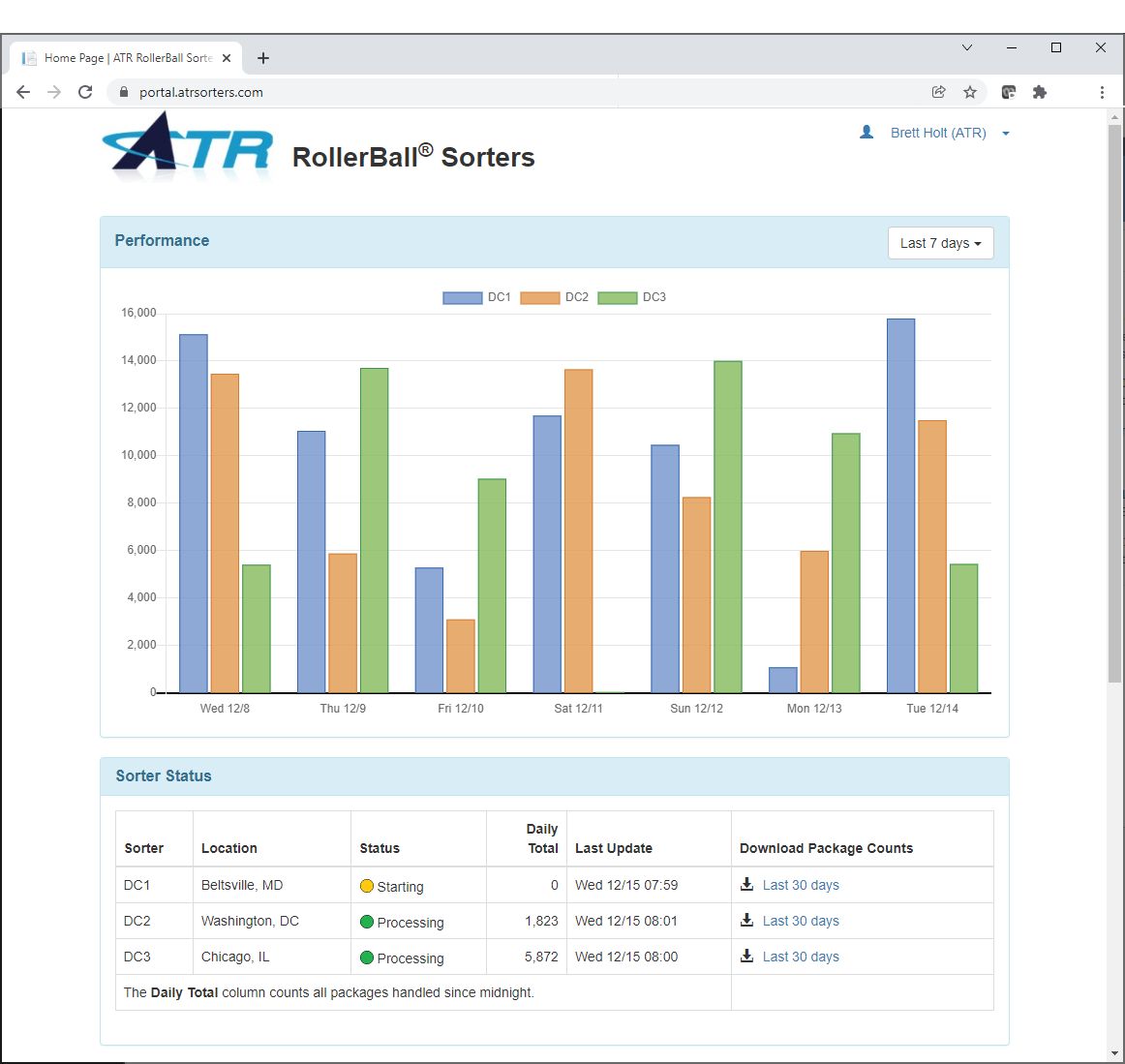

Remote Monitoring

RollerBall® sorters include built-in remote monitoring capabilities. You can check up on your company's sorters at any time with our web portal. Get status information or check on daily volume for valuable insights into how RollerBall® sorters are improving your bottom line.

The portal can be accessed from your desktop, laptop or on-the-go via your smart phone. The responsive design works well with both iPhone and Android devices.

Features include:

- Sorter status and current volume at a glance

- Package volume graph for the last 30 days

- Built-in weekly, bi-weekly and monthly views

- Downable statistics for each sorter

- Operators manual and other file downloads

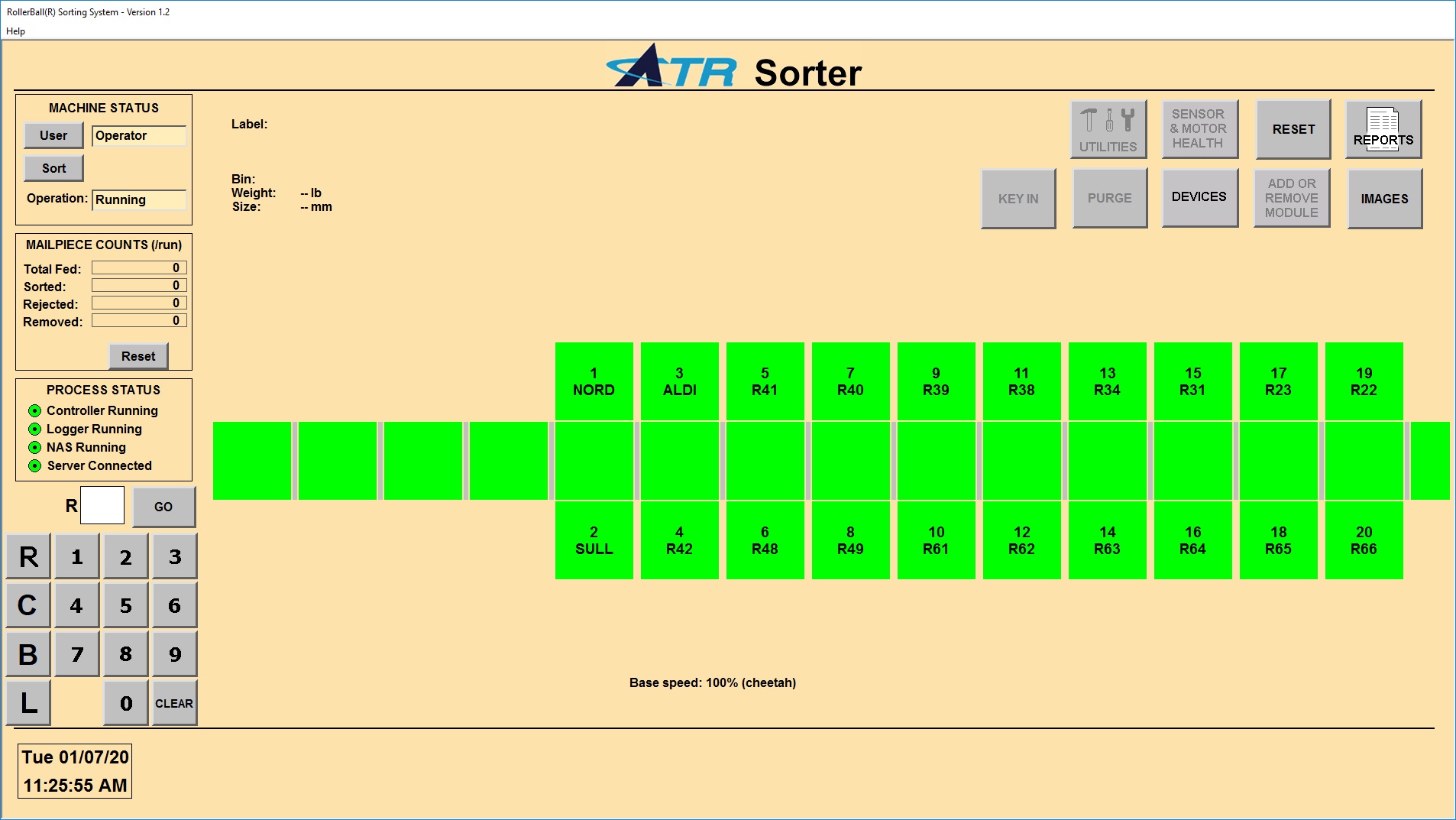

Software

Modular and Distributed

ATR’s patented solution places the control where it’s needed. Each sort module manages its own operation, communicating with upstream and downstream modules, and also with supervisory control. This modular approach ensures high performance, and easy system reconfiguration.

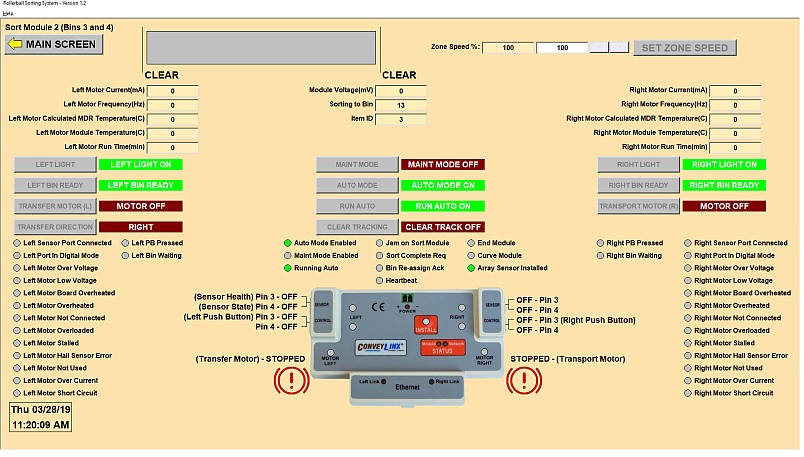

Supervisory Control

The supervisory control system is designed to easily integrate with external systems for sort assignments, reporting, and updates. Its Graphical User Interface (GUI) makes it easy to add or remove sort modules at any time. The sorter will automatically re-configure itself in response to layout changes. The owner/operator can reconfigure the sorter — there is no need to call in outside assistance when the sorter utilization plan changes.

Comprehensive Diagnostics

Graphical screens provide a wide range of diagostics. Operators and technicians can see the state of all sensors, check for error conditions, and activate all motors to test and troubleshoot operations. Event logs can show where jams are occurring, and identify incipient problem areas.

Interoperability

Integrates easily with your existing logistics system for sortation logic, reporting and monitoring. The sorter can work with your:

- Warehouse Management System (WMS)

- Warehouse Control System (WCS)

- Order Management System (OMS)

- Transportation Management System (TMS)

Stand-alone operation is also possible with the built-in sort plan editor.