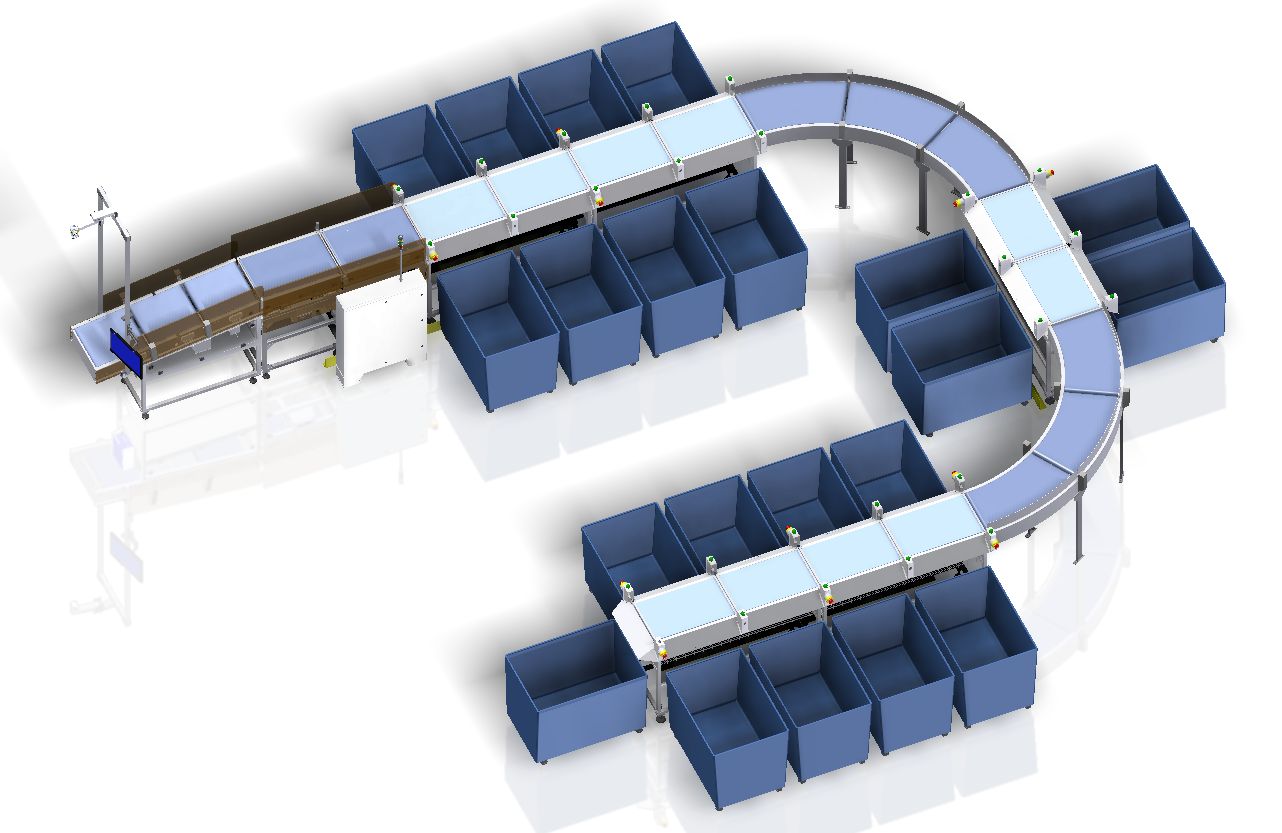

Puts your dispatch operation into overdrive

Moving up to a RollerBall® sorter allows you to handle more packages with fewer staff.

It also enables more complex and adaptable sort schemes, such as route optimization, that may not be feasible with manual sortation.

High Performance

Sort 1,800 - 2,700 packages per hour

(30 - 45 per minute).

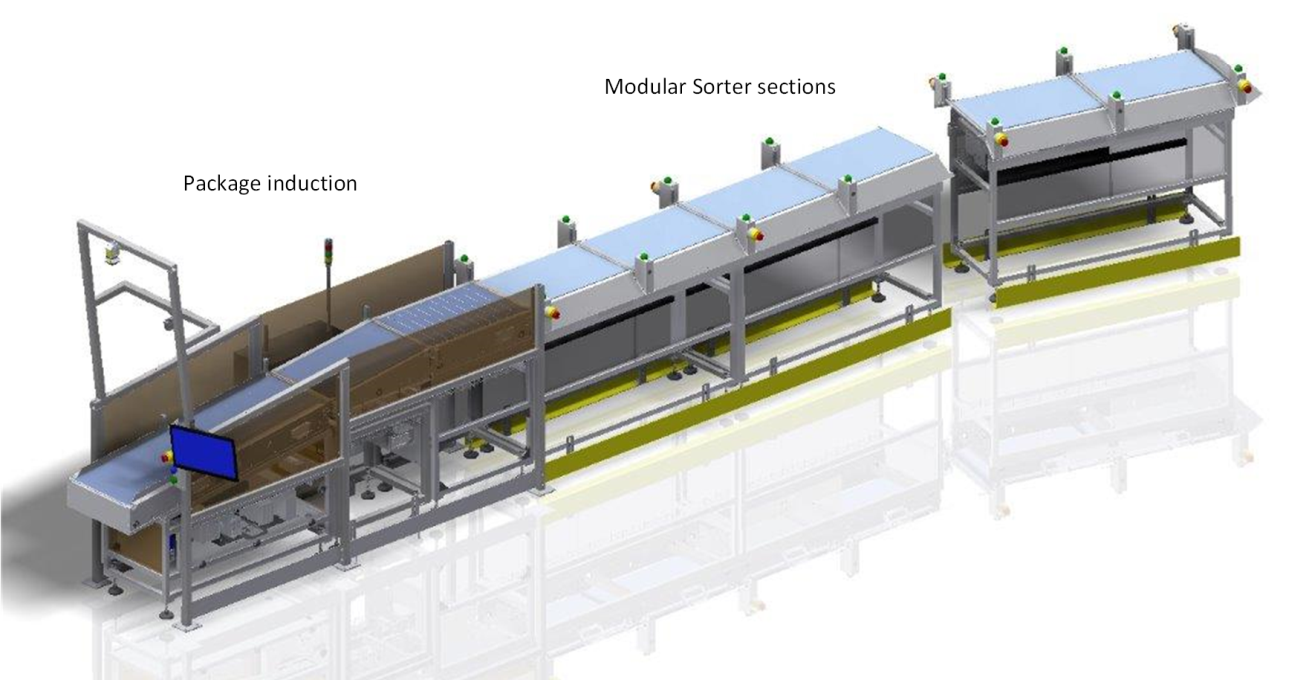

Modular and Flexible

Plug-and-play sections make it easy to

add sort points in the future.

Reliable

Proven design, built with

commercially available components.